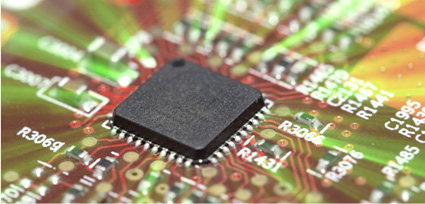

HAPRO produces turnkey installations in the field of thermodynamic engineering for almost all industries. Every installation is individually designed and built by our specialists according to customer specifications, whether as a complete installation or as part of an existing one. Thermodynamic systems create advantages in many automated production processes. Hot air works quickly, accurately, safely and, above all, cost-efficiently.

- Home

- Plant engineering

- HAPRO special-purpose equipment

HAPRO special-purpose equipment

Thermodynamic engineering: Plant engineering

We look forward to hearing your requests.

Contact us, we will be pleased to advise you.

WiTec Elektrotechnik GmbH

Hauptstraße 41

D-42799 Leichlingen / Witzhelden, Germany

Phone +49 (0) 2174 / 7901-0

Fax +49 (0) 2174 / 7901-41

Email: info@hapro.de