A manufacturer of electric toothbrushes had an idea to print colourful motifs on the brush heads. To this end, the head had to be heated to a specified temperature to enable a wafer-thin film to be applied in the next step. Preheating the head provides a better bond between the base medium and the film.

The installation concept:

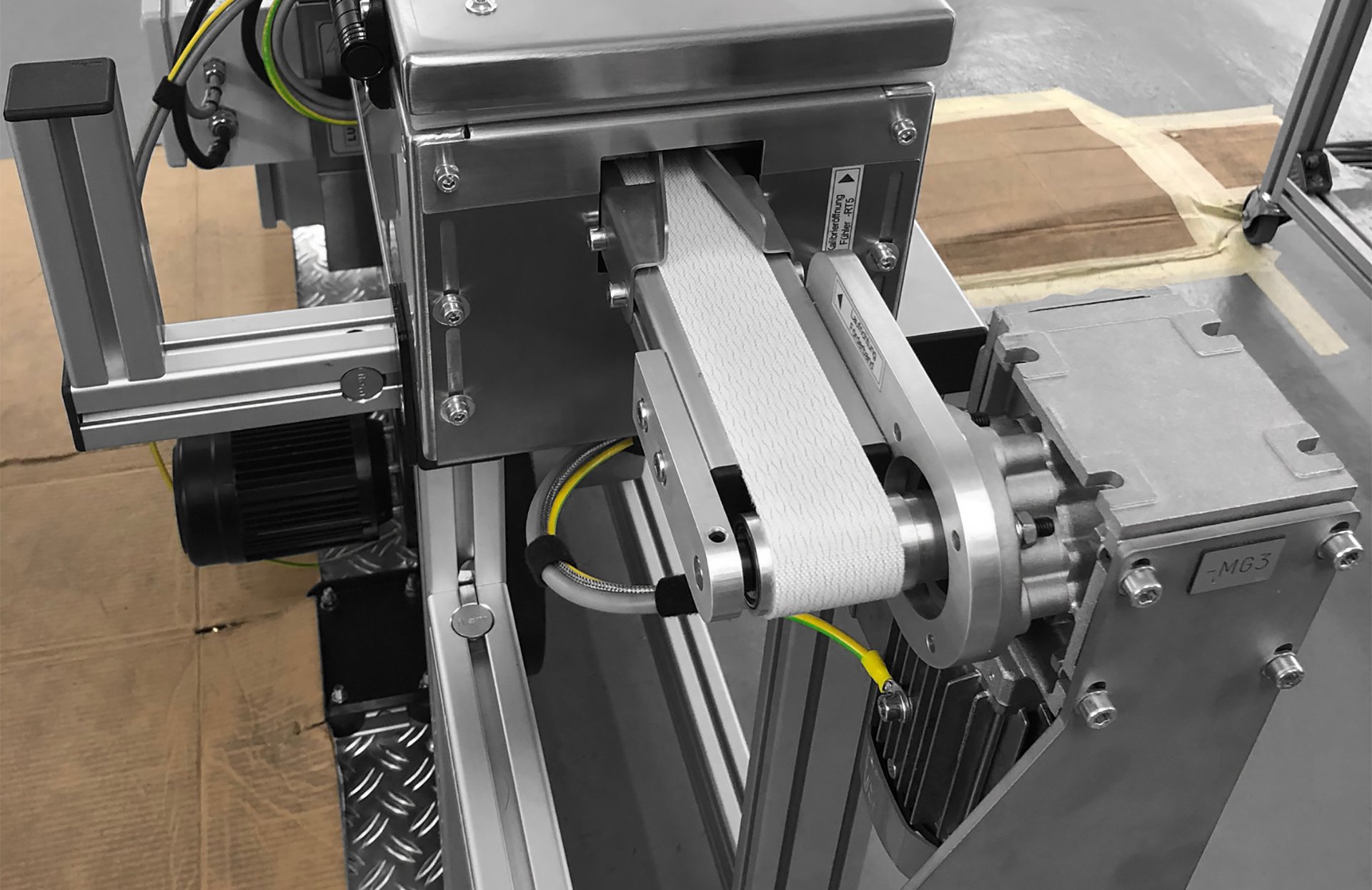

An installation with two heat ducts, each equipped with a combined air heater-blower, was designed. To achieve this, two 9 kW air heaters of the LE-R series and two medium pressure blowers were installed. The two belt sections for transporting the products are approx. 2 m long. The installation is PLC-controlled. The heated air is extracted and fed back into the process, which significantly reduces the amount of energy required.