A customer manufactures a wide range of different underfloor heating systems. The cable ends of the heater mats for electric underfloor heating systems must be shrunk-fitted and crimped for this purpose.

A recirculating system was developed in which the heater mats are fed to different positions on workpiece carriers. The products are manually fitted with PTFE heat shrink sleeves and shrunk-fitted in a specially developed heat chamber.

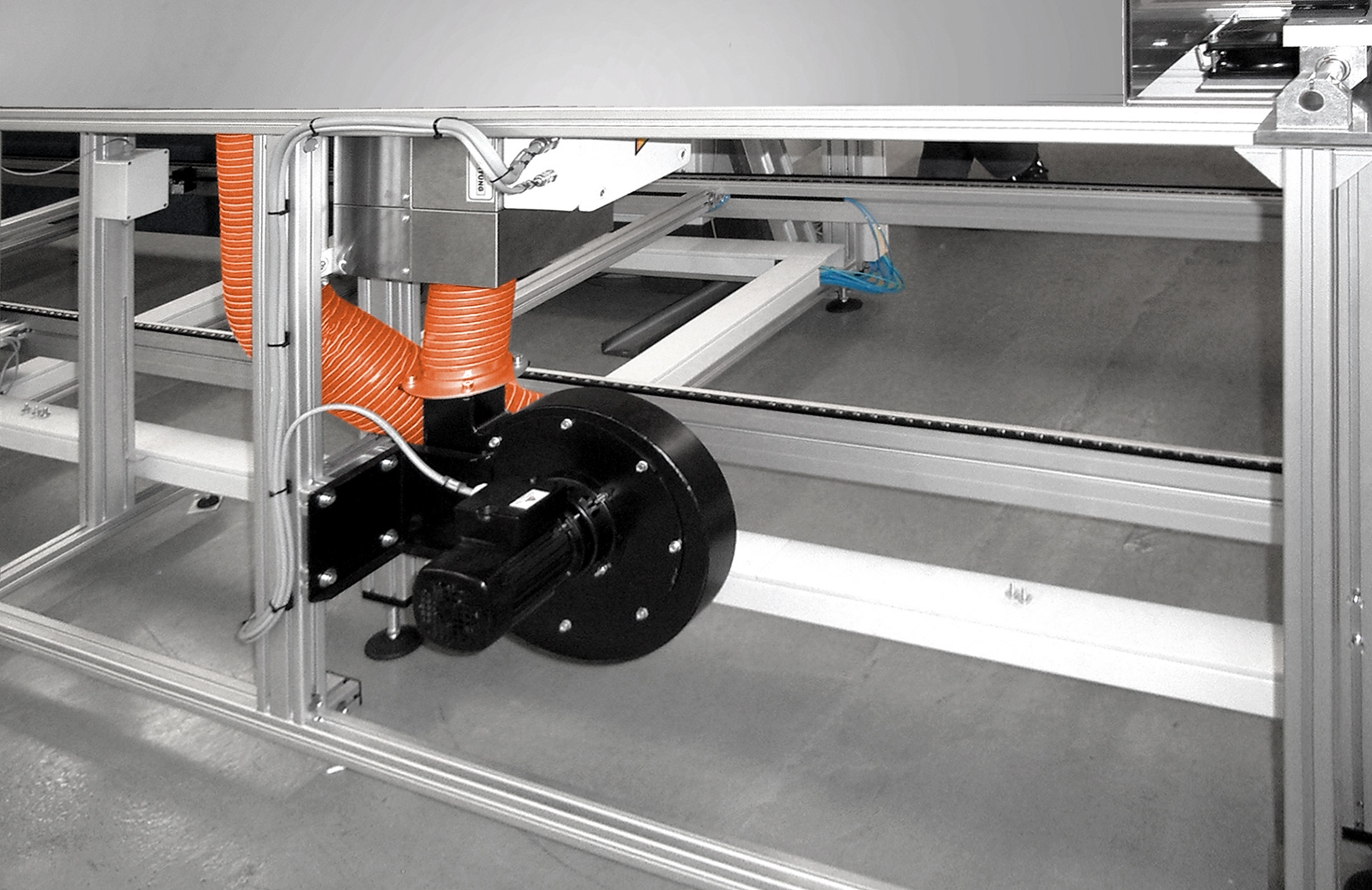

To this end, an LE-R air heater with nozzle unit and a medium-pressure blower were installed in the seven-metre-long installation. The shrinking process takes place at a temperature of approx. 400 °C. Finally, the cable ends are then crimped in a machine. The entire process is controlled by a PLC.